Fatigue tests

Complex stresses are becoming an increasingly important component of testing concepts. Strength analyses that use fatigue tests are a very accurate way to represent real-life scenarios.

In cases where the component stress is difficult to depict using simulated means, fatigue tests are the next logical step.

Step 1

With a fatigue test, the acting forces and moments are measured while the test object is in operation.

Step 2

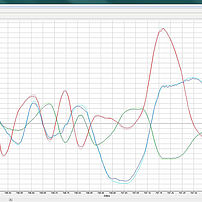

The measured signal is analysed in the second phase. Non-damaging vibrations can be removed, for example, to compress the collective. The collective must be defined with the service life and the areas of application (e.g. motorways, country roads or even unsurfaced roads) taken into account.

Step 3

The signal that is determined is simulated on the laboratory test bench. This reproducibility means that tests can also be repeated and assessed at a later stage (when integrating newer systems, for example).

When it comes to fatigue tests – one of our areas of expertise – we can offer solutions for determining load collectives, carrying out bench tests and performing crack analyses on the test object.